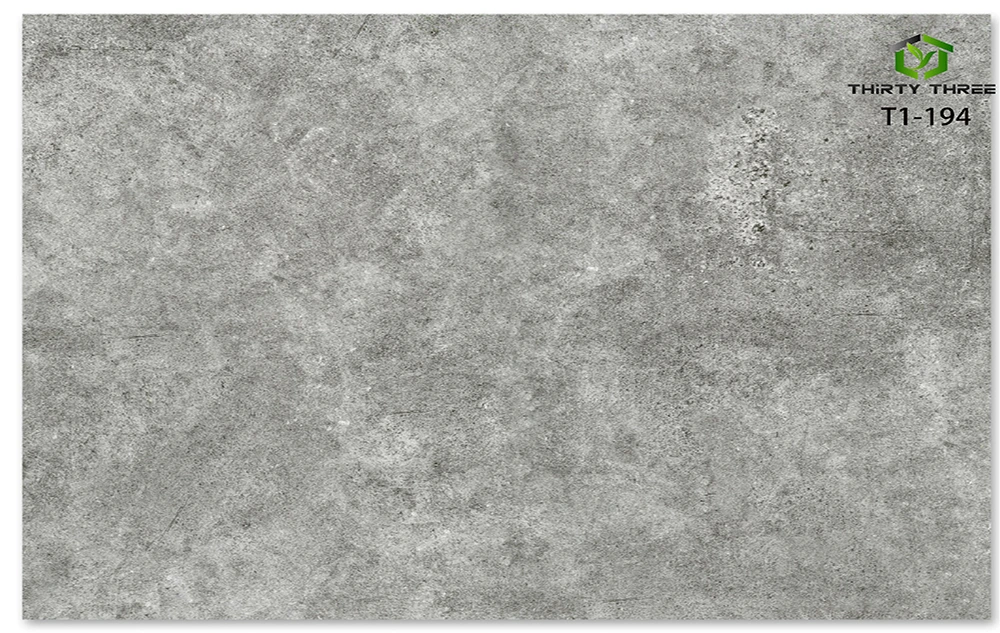

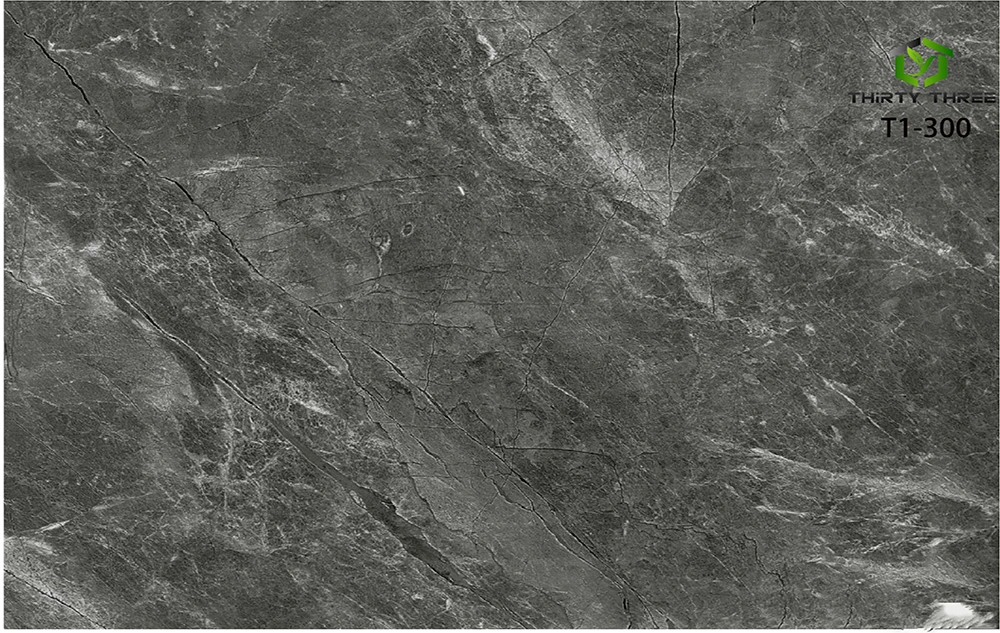

UV board is a plate with a surface protected by UV treatment. UV paint is UV-curable paint, also known as light-triggered paint. The board formed by UV paint on particleboard, density board and other boards, and then dried by UV light curing machine, can achieve industrial production because of its easy processing, bright color, wear resistance, strong chemical resistance, long service life, high requirements for mechanical equipment and process technology, and has the characteristics of resistance to moisture and deformation: Primer using solvent-free 4E green high-grade paint, non-volatile, non-toxic and environmental protection; After curing, it has a high light antibacterial effect and is an ideal decorative plate.

The exterior UV color plate is based on high-density fiber cement board as the base material, the thickness of the board is generally 12mm, the use of UV light curing process to paint the surface of the plate decoration, attach the paint coating on the surface of the plate, through the irradiation of UV light, the instant curing film, and high solid content, high hardness. It is mainly used for the decoration of external walls, and good decoration can make the decoration of buildings glow with brilliant colors.

- Features

High surface smoothness: the mirror highlight effect is obvious.

The paint film is full: the color is full and attractive.

Environmental health: Usually paint board paint is not good, and there are volatile substances (VOC) release, UV board to solve the century environmental problems. Not only does it not contain volatile substances such as benzene, but also forms a dense curing film through ultraviolet curing, reducing the release of the substrate gas.

No fading: Through comparative experiments, UV panels have better physical and chemical properties than traditional panels, ensure that UV panels do not fade for a long time, and solve the color difference phenomenon.

Scratch resistance: The higher the hardness, the brighter the grinding, and the long-term deformation after curing at room temperature.

Acid and alkali corrosion resistance: UV board can resist the corrosion of various acid and alkali disinfectants. The reason for the formation of the above characteristics of the UV board is that because of the chemical reaction between the paint and the ultraviolet light, a dense protective film is formed, and the molecular distance between the dense protective film is very small, smaller than the water molecules and acetic acid molecules, so it has the effect of waterproof and stain resistance. However, the white UV board is easy to yellow when it sees the sun, and the industry can not solve this problem.

- Application